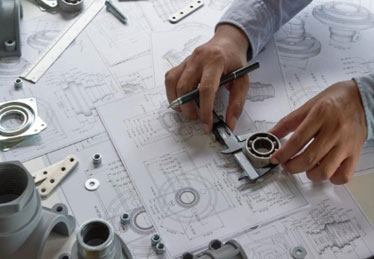

Fabrication Drawing and Method Statement

Our Project team ensure delivery and installation of quality product within time. We achieved it with better coordination between Project, engineering, production teams. Fabrication drawings, Quality Plan, inspection/verification report made and used for monitoring. Raw material and consumable inspection /acceptance as per QP. Tool machinery validation, skilled manpower further training is a must at MMW for betterment of product and services. Site installation as per approved drawing and Method Statement.

Steel Fabrication

We have two units of steel fabrication workshops in misfah (within Capital city-Muscat Area) fully equipped with required infrastructure, skilled manpower. Our Production and Quality Assurance put very hard efforts to achieve customer satisfaction. We fabricate items like plant steel structure, industrial metal piping, equipment, spreader beams, skids, steel platforms, non-pressure vessels, trench cover, instrument rack, lifting basket, staircase, spiral staircase, stainless steel handrail, Cat ladder, cage ladder, STP plant steel frames, metal brackets, high security grill, pipe support, flanged pipe, puddle, storage and wash tank, silos, hopper, reflector tube, fire bucket set, swing and sliding gates proudly servicing all governate and sectors in Sultanate of Oman.

Installation & Commissioning

Packing list /delivery note/ dispatch plan done thoroughly. Safely loading/unloading, storage as per quality plan. Site installation as per method statement. Erection manual made for, particular site requirement. Safe work environment achieved. HSE training, tool box talks and monitoring are tools to achieve zero injury/ zero loss. Proper equipment, machinery and support provided to each site for smooth installation at sites.

Our workers are trained in workplace safety procedures:

- HSE

- Lockout-tagout (LOTO)

- Confined Space Entry

- Fire Safety, Hazard Assessment

- Hot Work permits

- Personal protection equipment (PPE).

Maintenance

We are doing scheduled/Annual maintenance of plants, we conduct site structural inspections, validating the integrity or steel assets, providing maintenance reports, recommendations detailed drawings for repairs.

- Visual inspection for corrosion

- Inspect for pitting

- Inspect for holes in parent material

- Inspect for thinning of parent material

- Dye-penetrant testing for cracks

- Re-painting, re-galvanizing or retouching of surface protection, depending on the application.

- Bracing, strengthening and replacing corroded steel members.

- Complete steel structure replacement at end of design life.

Quality Assurance

Our instruments are calibrated. Our methods are formatted and monitored by full time, qualified QC personnel. Inspection and testing is conducted when purchased materials are received, during production, and prior to shipping of finished products. In addition, you’re welcome to visit and/or schedule a third-party audit. Customer satisfaction is paramount for us.

Product List

We have expertise in stainless steel and carbon steel fabrication, our product list includes

- Specialized plant structure, spreader beams, supports and brackets

- Industrial metal piping and pipe supports

- Non pressure vessels and industrial equipment

- Metal works like metal decking, handrails, gates, grill, ladder, stairs, etc

- Steel frames, feature walls, skids, lifting baskets, instrument racks, crowd barrier.

- Stainless steel silo, sump, gutter, tanks etc

- Factory Shed, warehouse, carparking shed, instrument shed.

- Fabricated pipe flanges, puddle, specialized items

Shutdown and Refurbishment

We have experienced teams for shutdowns and revamp, we have expertise for revamp of static equipment, machine bed, piping and support structure. we conduct site structural inspections, validating the integrity or steel assets, providing maintenance reports, recommendations and effecting repairs as needed.

- Visual inspection for corrosion

- Dye-penetrant testing for cracks

- Re-painting, re-galvanizing or retouching of surface protection, depending on the application.

- Bracing, strengthening and replacing corroded steel members.

- Complete steel structure replacement